Transforming Quality Control with Manufacturing ERP Software

Skyland ERP delivers advanced cloud-based manufacturing ERP software in Pakistan, built to optimize production workflows. It precisely tracks material usage, enables efficient capacity planning, and manages subcontracting processes seamlessly. Designed to boost operational performance, Skyland ERP helps businesses achieve greater control, accuracy, and efficiency in manufacturing.

Simplify production planning and shop floor operations with Skyland ERP, a leading choice for manufacturing businesses in Pakistan. This all-in-one solution integrates customer management, sales, inventory, purchasing, accounting, and financial reporting, ensuring smooth collaboration across every department in your organization.

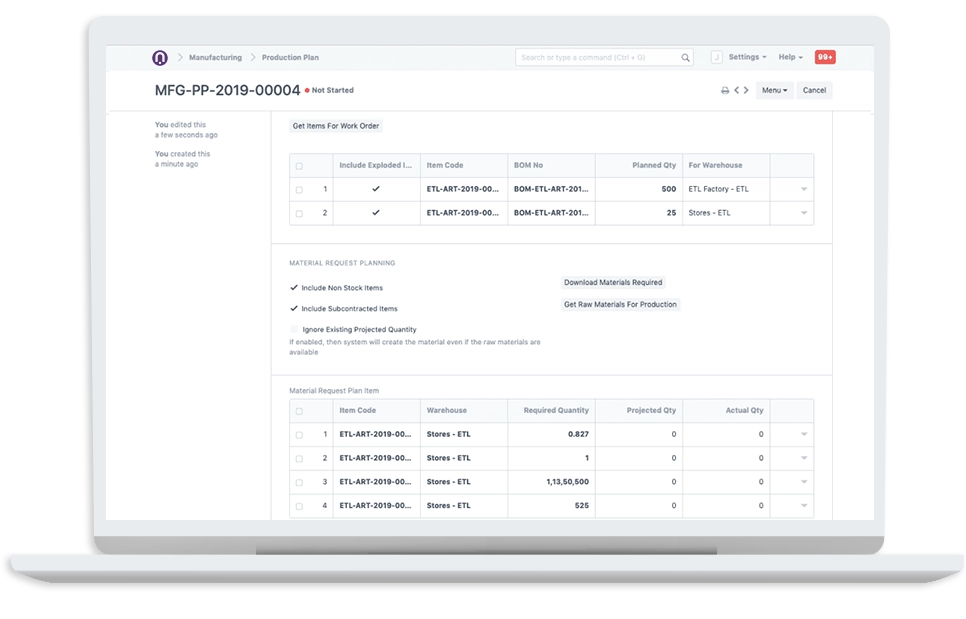

The bill of materials feature in Skyland ERP is a vital component of cloud-based manufacturing software in Pakistan. It delivers accuracy and consistency by offering a detailed breakdown of product codes, part details, quantities, and associated costs, ensuring smooth and reliable production planning.

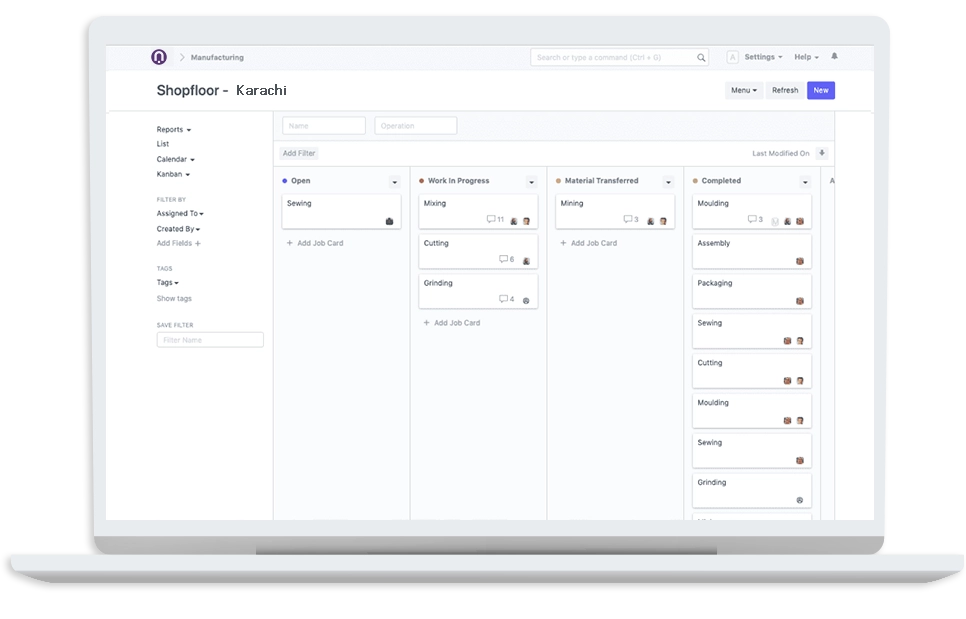

Skyland ERP, a top-tier manufacturing ERP software in Pakistan, provides features like job cards, operations tracking, and workstation management. These tools automatically record daily shop floor activities, allowing you to monitor job tasks in real time, track employee assignments, and view each work order's current and upcoming steps—all from one centralized dashboard.

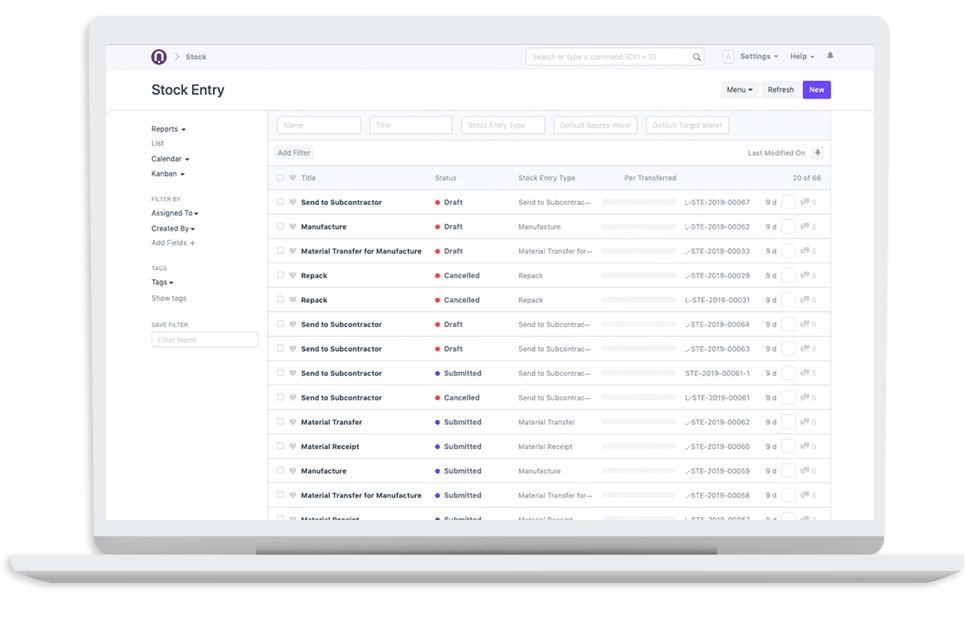

For businesses that work with external manufacturers in Pakistan, Skyland ERP’s subcontracting feature is essential. It helps manage required materials, monitor supplier and workforce performance, and calculate the value of finished goods based on material and service costs, ensuring smooth and cost-effective outsourced production.

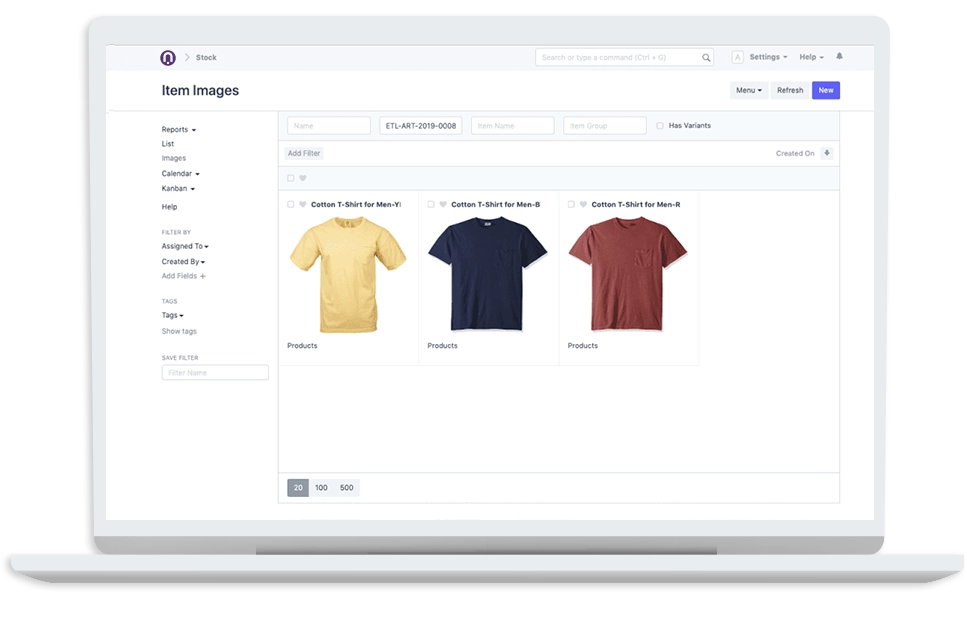

When producing multiple versions of a product, like different types of t-shirts, Skyland ERP helps you stay organized. You can set up a main product as a template and manage each variation—such as color or size—as a separate item variant. This structure simplifies inventory tracking and boosts efficiency in managing product details.

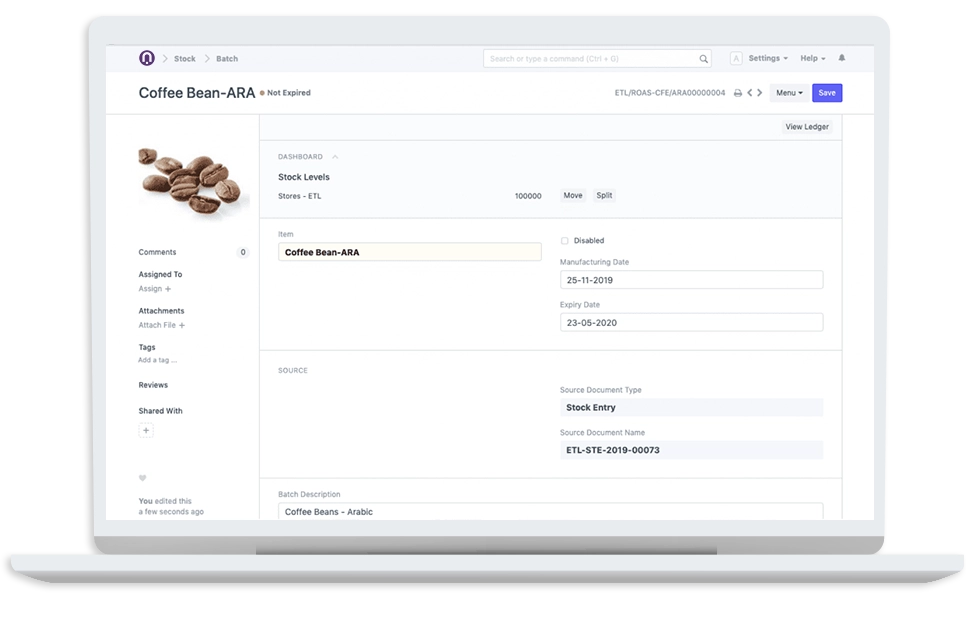

Managing items in batches is simple with Skyland ERP, one of Pakistan’s leading ERP solutions. It provides real-time stock updates while tracking production and expiry dates for each batch. The system also supports barcode scanning through your device’s camera, enabling quick stock checks and smarter inventory decisions.

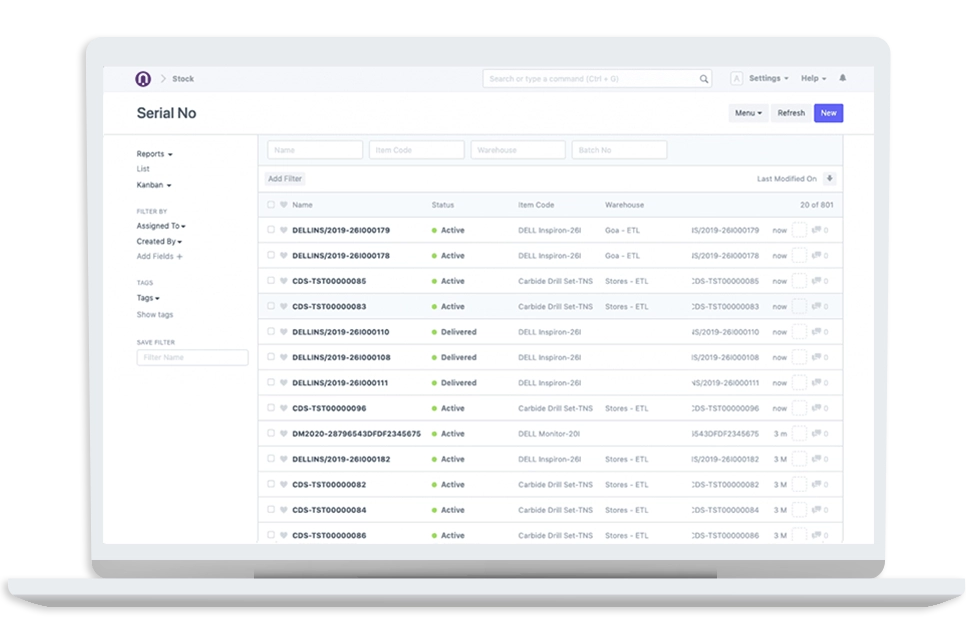

Skyland ERP stands out in Pakistan’s manufacturing industry for its powerful serial number tracking capabilities. It allows you to automatically generate unique serial numbers for items and supports barcode scanning for fast, accurate inventory verification and control.

Skyland ERP enables precise tracking of material usage during sales orders or production needs. It offers clear visibility into requirements for serialized or batched items, helping you reduce costs, prevent waste, and maintain efficient resource planning.

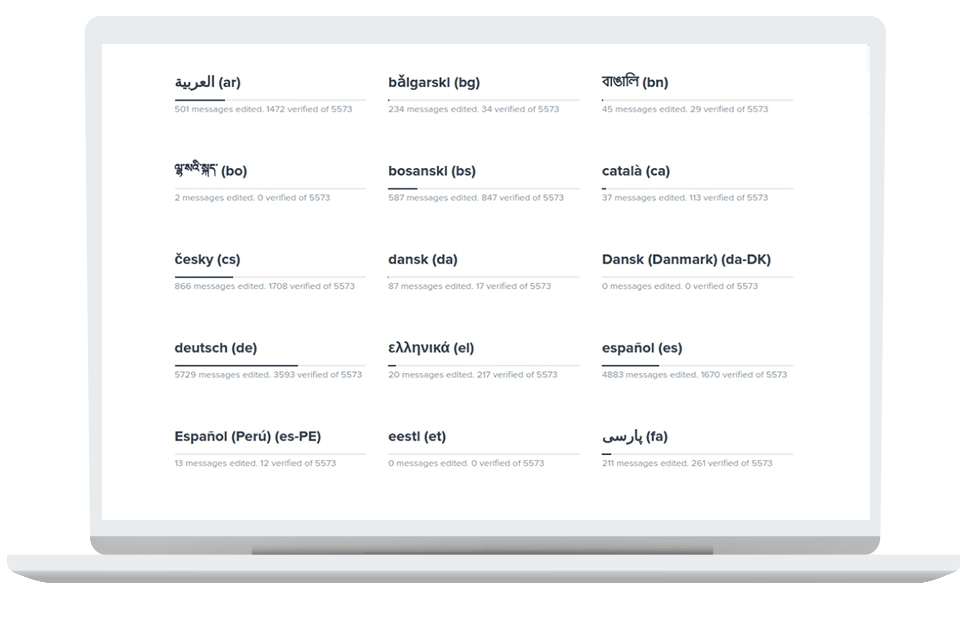

Operate your software in the language you’re most comfortable with. This feature enhances usability and delivers a more intuitive and personalized experience across your business operations.

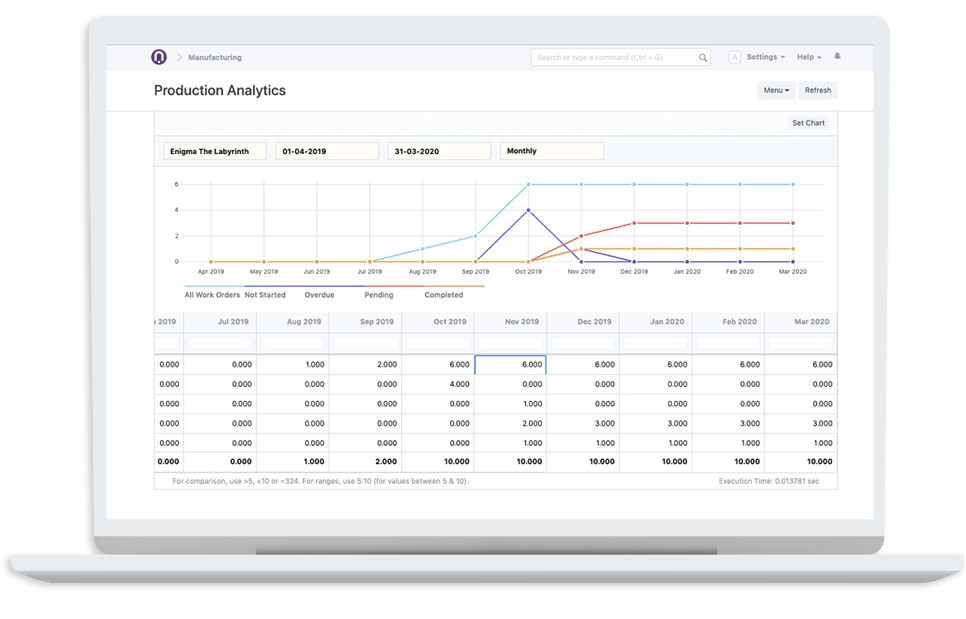

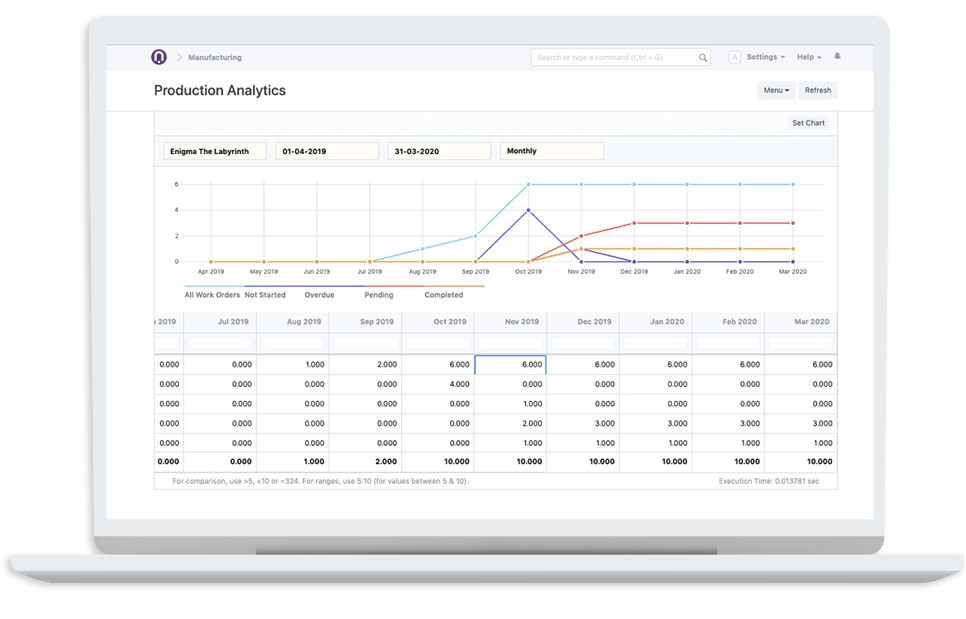

Manufacturing management software enhances operational efficiency, reduces costs, improves product quality, streamlines inventory control, and provides valuable insights through advanced data analysis.

Manufacturing management software manages production scheduling through real-time monitoring, resource allocation, demand forecasting, capacity planning, work order tracking, and seamless integration across departments.

Key features include production planning, inventory management, quality control, reporting and analytics, supply chain management, and system integration for smooth operations.

It tracks labor and machines through real-time data collection, workforce scheduling, machine utilization monitoring, performance analytics, and system integration for seamless data flow and detailed reporting.

It integrates with ERP platforms, accounting tools, and other business applications using APIs, built-in connectors, and interfaces to enable seamless and efficient data exchange.